How Bearing Misalignment Can Cause Major Downtime—and How to Prevent It

June 19, 2025 1:26 pm Leave your thoughtsIndustrial operations rely heavily on the seamless performance of machinery to maintain productivity and profitability. In cotton ginning operations and other manufacturing sectors, one of the most overlooked threats to machine reliability is bearing misalignment. Despite their small size and seemingly simple function, bearings play a critical role in supporting rotating components and ensuring mechanical motion runs smoothly. When bearings are misaligned, however, the consequences can be severe—ranging from increased wear and tear to complete equipment failure. This blog explores how bearing misalignment leads to mechanical downtime, its effects on cotton gin equipment, and how to prevent it from derailing your operations.

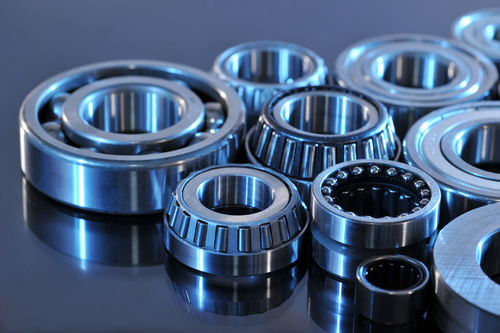

The Mechanics and Consequences of Bearing Misalignment

Bearing misalignment occurs when the centerlines of the shaft and the bearing housing are not perfectly aligned. This can happen due to improper installation, structural shifts, thermal expansion, or excessive load. While slight misalignment may seem harmless at first, even a small deviation can cause uneven load distribution within the bearing, leading to increased friction, localized stress, and ultimately, premature failure.

One of the most immediate effects of bearing misalignment is increased operating temperature. The friction caused by skewed alignment generates excessive heat, which can degrade the lubricant more rapidly and cause metal-to-metal contact. This speeds up the rate of wear, reducing the effective lifespan of the bearing and potentially damaging adjacent components.

The ripple effects of bearing misalignment extend beyond the bearings themselves. Misalignment can transmit vibration throughout the machinery, destabilizing gears, pulleys, and other mechanical elements. Over time, this accelerates wear and can lead to cascading failures within the system. Moreover, these issues are often subtle in the early stages, making them difficult to detect without regular monitoring.

The cost implications of bearing misalignment are significant. Unscheduled maintenance, replacement of damaged parts, and unplanned production halts contribute to mechanical downtime that affects the bottom line. In industries where uptime is closely tied to revenue—such as cotton processing—this kind of disruption can have a pronounced financial impact.

Bearing Misalignment in Cotton Gin Equipment

Cotton gin equipment operates in a high-dust, high-vibration environment that places extraordinary demands on bearings. The machinery used in ginning—such as saw gins, lint cleaners, and seed conveyors—relies heavily on precise alignment to function efficiently. Given the high rotational speeds and heavy loads involved, even slight bearing misalignment can rapidly degrade machine performance.

The challenge is compounded by the conditions in which cotton gins operate. Debris and cotton lint can infiltrate bearing housings, contributing to wear. Additionally, temperature fluctuations between day and night, or between operational and idle states, can cause components to expand or contract. Without proper thermal compensation in the design or installation, this can lead to a gradual shift in alignment.

In cotton gins, mechanical downtime caused by bearing misalignment doesn’t just halt operations—it can result in missed harvest processing windows, contractual penalties, and degraded cotton quality. A single hour of downtime during peak season can translate to thousands of dollars in lost productivity. Moreover, because ginning operations are often seasonal, there’s little room for error or delay. This makes proactive maintenance and alignment verification not just a good practice, but a necessity.

Identifying the Warning Signs of Industrial Bearing Failure

One of the major difficulties with bearing misalignment is that it often goes unnoticed until significant damage has occurred. However, there are telltale signs that operators and maintenance personnel can monitor to catch issues before they escalate into full-blown failures.

The most common indicator is abnormal noise. Bearings that are misaligned tend to produce a whirring, grinding, or clicking sound that differs from the normal hum of machinery. These sounds may be intermittent at first but often grow more consistent and louder over time as the damage progresses.

Vibration is another key indicator. Misaligned bearings generate irregular and unpredictable vibrations, which can be detected using vibration analysis tools. Regular condition monitoring with sensors can help create a baseline and alert operators when vibration patterns deviate significantly.

Thermal imaging is also a valuable diagnostic tool. Bearings that are running hotter than expected—especially when compared with adjacent bearings—often signal misalignment or lubrication issues. Over time, operators can use infrared cameras to build a thermal profile of their equipment, allowing for easier detection of anomalies.

Physical inspection can reveal visible signs such as uneven wear patterns on bearings, cracked housings, or lubricant leakage. While inspections require scheduled downtime, they are crucial in preventing more extensive shutdowns due to industrial bearing failure.

How to Prevent Bearing Misalignment and Downtime

Preventing bearing misalignment starts with proper installation. Ensuring that shafts, housings, and couplings are precisely aligned at the outset is critical. Using laser alignment tools during installation can greatly increase accuracy compared to traditional straightedge or dial methods. These tools offer real-time feedback and allow for fine adjustments that minimize the chance of initial misalignment.

Lubrication plays a dual role in preventing bearing failure. Not only does it reduce friction and wear, but it can also act as a diagnostic tool. Monitoring lubricant conditions through regular sampling helps detect contamination, oxidation, and overheating—often symptoms of misalignment. Using the correct type and amount of lubricant based on load and speed requirements is also essential.

Incorporating flexible couplings can help compensate for minor misalignments caused by thermal expansion or load fluctuations. These couplings absorb and distribute forces more evenly, protecting the bearing from excessive stress. However, this is not a substitute for proper alignment, but rather a safeguard against operational variances.

Routine maintenance and alignment audits should be built into the standard operating procedure. Predictive maintenance using vibration analysis and temperature monitoring provides real-time insights into bearing health. This allows for planned interventions before misalignment leads to major mechanical downtime.

Training personnel is another crucial preventative step. Ensuring that operators and maintenance staff understand the symptoms, causes, and prevention strategies for bearing misalignment empowers them to act quickly and effectively. A small investment in training can pay large dividends in equipment reliability.

The Long-Term Impact of Addressing Bearing Misalignment

Addressing bearing misalignment isn’t just about reducing mechanical downtime—it’s about ensuring the long-term reliability, efficiency, and profitability of your operations. When properly aligned, machinery experiences less vibration, reduced energy consumption, and fewer breakdowns. This leads to a more predictable maintenance schedule, longer equipment lifespan, and increased production output.

For cotton gin equipment, where high throughput and short operational windows are the norm, reducing the risk of industrial bearing failure is critical. A single instance of unscheduled downtime during the harvest season can cause cascading scheduling issues, lost revenue, and strained customer relationships. Conversely, a well-maintained, well-aligned system promotes smoother operations and greater output consistency.

There is also a safety aspect to consider. Misaligned components increase the likelihood of unexpected mechanical failure, which can pose risks to nearby workers. By minimizing the chance of catastrophic failures, facilities also reduce potential liability and improve overall workplace safety.

Conclusion

Bearing misalignment is a silent saboteur in industrial environments. It undermines performance, drives up maintenance costs, and causes mechanical downtime that few operations can afford. By understanding the causes, recognizing the symptoms, and implementing robust prevention strategies, industries like cotton ginning can safeguard their operations from costly interruptions. Proactive management of alignment not only preserves the integrity of machinery but also ensures long-term success in highly competitive sectors.

Need Cotton Mill & Cotton Gin Components in Lubbock, TX?

Welcome to M.B. McKee Company, Inc. M.B. McKee Company, Inc. has been serving our local community of Lubbock since 1943. Locally owned and family operated, we provide great customer service and solutions for ongoing issues. With over 70 years of experience, our products, services, and engineering will always exceed your expectations. Our products include bearings, belts, chains, conveyor systems, gearing, lifts, motors, drives, product separation, tools, valves, and fittings. Our engineering division also provides general formulas, NEMA motor frames, elevator legs, screw and belt conveyors, lift charts, components from Baldor and Flexco, and various interchangeable parts. Contact us today to learn more about what we can do for you!

Categorised in: Mechanical Bearings

This post was written by Orlando Washington