The Importance of Preventive Maintenance for Industrial Equipment in Harsh Texas Conditions

August 9, 2025 1:24 pm Leave your thoughtsIn the expansive industrial landscape of Texas, where dust storms, temperature extremes, and high humidity levels are part of daily operations, the stakes for keeping industrial equipment functioning at peak efficiency are higher than ever. Preventive maintenance for industrial equipment is not just a best practice—it is a vital lifeline for ensuring productivity, safety, and cost control. This becomes especially significant in cities like Lubbock, TX, where industrial supply chains rely heavily on the consistent performance of heavy-duty machinery in hostile environmental conditions.

Understanding the regional climate challenges and their direct impact on industrial performance is crucial. Harsh Texas operating conditions present a unique and persistent threat to the integrity of mechanical systems, electronics, and hydraulic systems. If companies wish to extend the lifespan of their equipment and reduce downtime, establishing a robust preventive maintenance plan is not optional—it’s imperative.

The Unique Impact of Texas Weather on Industrial Equipment

Texas is known for its extremes—scorching summer heat that often exceeds 100°F, sudden cold snaps in winter, long droughts, high winds, and even frequent dust storms, especially in the western and panhandle regions like Lubbock. Each of these environmental conditions can severely impact the functionality of industrial equipment.

Heat accelerates the wear and tear on mechanical components, increases the risk of overheating in engines, and puts stress on lubricants and hydraulic fluids, reducing their effectiveness. Dust particles, omnipresent in dry and windy environments, infiltrate seals and joints, damaging sensitive components and causing premature failure. Humidity and rainfall, on the other hand, create an entirely different risk profile, leading to rust, corrosion, and electrical shorts in exposed or poorly insulated systems.

In Lubbock, TX—where industrial supply operations range from agriculture to manufacturing to energy—these environmental factors demand heightened vigilance. Equipment used in these areas must be protected against these threats through routine inspections, regular lubrication, filter changes, and part replacements that preemptively solve problems before they manifest in catastrophic breakdowns.

Defining Preventive Maintenance for Industrial Equipment

Preventive maintenance for industrial equipment refers to the systematic, scheduled servicing of machines to prevent potential failures and extend their operating life. It includes activities such as checking fluid levels, inspecting belts and chains, tightening bolts, cleaning filters, testing electrical components, and replacing worn-out parts.

Unlike reactive maintenance—which occurs after a breakdown—preventive maintenance is proactive. It aims to reduce downtime, increase reliability, and ultimately lower the total cost of ownership. In a competitive industrial market where operational efficiency directly impacts profitability, this proactive approach is a game-changer.

The goal is to identify issues at their earliest stages. For example, a small vibration in a pump motor may seem inconsequential, but it could indicate an impending bearing failure. If left unchecked in harsh Texas operating conditions, that failure could snowball into a complete system shutdown, with costly implications. Preventive maintenance ensures that red flags like these are detected and resolved long before they become emergencies.

The Financial and Operational Benefits in Lubbock, TX

For businesses based in Lubbock, TX, preventive maintenance offers a crucial strategic advantage. Industrial supply chains in this region are under constant pressure to deliver reliably, often across wide rural areas with limited access to rapid repairs or spare parts. In this context, downtime is more than a nuisance—it can bring operations to a standstill, causing ripple effects through production lines, distribution centers, and end-user satisfaction.

By investing in preventive maintenance, companies in Lubbock can avoid the high costs associated with emergency repairs, unscheduled downtimes, and part replacements. Over time, the savings are substantial. Regular maintenance extends the life of critical equipment, delays capital expenditures for new machines, and helps maintain consistent productivity.

Moreover, preventive maintenance contributes to workplace safety. Equipment that is well-maintained is less likely to fail in dangerous ways. For example, hydraulic failure on a loader in a high-heat environment could result in injury or worse. With a proper maintenance regimen, these risks are significantly reduced.

In addition to safety and cost savings, many insurance providers offer lower premiums for businesses that can demonstrate a consistent preventive maintenance schedule, further reinforcing the financial incentive.

Leveraging Technology for Maintenance Optimization

Modern preventive maintenance is no longer limited to checklists and paper logs. Today, industrial businesses in Lubbock and across Texas are embracing technology to bring precision and efficiency to their maintenance programs. Predictive maintenance, a close relative of preventive maintenance, utilizes sensors and IoT (Internet of Things) technology to monitor real-time conditions such as temperature, vibration, pressure, and oil quality.

This data-driven approach allows maintenance teams to make smarter decisions about when and how to service equipment, rather than relying solely on calendar-based schedules. For example, a machine that is operating well under capacity may not need as frequent maintenance, while another working near its performance limits in harsh Texas operating conditions may require more frequent attention.

Computerized Maintenance Management Systems (CMMS) are also gaining traction in Lubbock’s industrial supply sector. These platforms provide digital records of all maintenance activities, automate scheduling, issue alerts for upcoming services, and help track parts inventory. As a result, operations become more streamlined, and maintenance teams can be more proactive and strategic in their planning.

Companies that adopt these technologies often see a measurable improvement in uptime, resource utilization, and repair turnaround times. With harsh conditions in Texas making every operational hour count, these gains can be critical.

Building a Culture of Maintenance Excellence

Ultimately, preventive maintenance for industrial equipment must go beyond checklists—it must become a part of the company’s culture. In places like Lubbock, TX, where weather and distance pose additional logistical hurdles, embedding maintenance awareness across the workforce can make a significant difference.

This cultural shift starts with training. Operators and technicians should be equipped not only with the skills to perform basic inspections but also with the understanding of why their actions matter. When personnel recognize the value of maintenance in protecting equipment and preventing downtime, they are more likely to report early warning signs, follow proper protocols, and treat machinery with care.

Management plays a key role by investing in training, incentivizing preventive behaviors, and enforcing accountability. Maintenance should not be seen as a cost center but as a strategic asset that contributes to profitability and safety.

Communication between departments is also vital. When production, maintenance, and procurement teams are aligned, the company can better plan downtime, source parts in advance, and make smarter long-term investments in durable equipment suitable for Texas’s challenging environment.

In summary, the businesses that succeed in Lubbock and other Texas industrial regions will be those that understand the true cost of equipment failure and the immense value of staying ahead of it through structured, intelligent preventive maintenance.

Conclusion

Preventive maintenance for industrial equipment is the linchpin of operational excellence in harsh Texas operating conditions. From the dusty plains of Lubbock to the humid Gulf Coast, industrial businesses face an uphill battle against environmental wear and tear. But with the right strategies—rooted in routine care, empowered by technology, and embraced culturally—this challenge becomes a manageable one.

For industrial supply companies in Lubbock, TX, the path forward is clear: protect your investments, empower your workforce, and prioritize maintenance before breakdowns happen. The result? Stronger performance, safer operations, and a bottom line that reflects resilience, not reactivity.

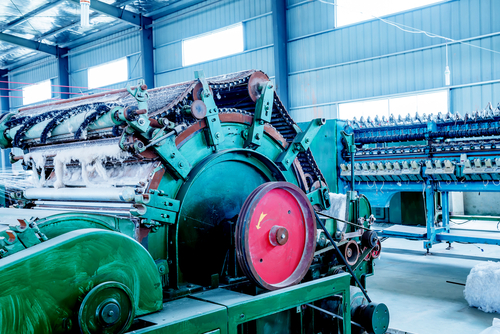

Need Cotton Mill & Cotton Gin Components in Lubbock, TX?

Welcome to M.B. McKee Company, Inc. M.B. McKee Company, Inc. has been serving our local community of Lubbock since 1943. Locally owned and family operated, we provide great customer service and solutions for ongoing issues. With over 70 years of experience, our products, services, and engineering will always exceed your expectations. Our products include bearings, belts, chains, conveyor systems, gearing, lifts, motors, drives, product separation, tools, valves, and fittings. Our engineering division also provides general formulas, NEMA motor frames, elevator legs, screw and belt conveyors, lift charts, components from Baldor and Flexco, and various interchangeable parts. Contact us today to learn more about what we can do for you!

Categorised in: Cotton Gin Maintenance

This post was written by Orlando Washington