Common Issues and Troubleshooting Tips for Bearings and Components in Agricultural Equipment in Amarillo, TX

March 7, 2025 7:26 pm Leave your thoughtsAgricultural equipment plays an essential role in the success of farming operations in Amarillo, Texas, a region where the economy heavily relies on the agriculture industry. From large tractors to harvesters and irrigation systems, the machinery used on farms is integral to the efficient and effective running of daily operations. However, like all machinery, agricultural equipment faces wear and tear over time, and components like bearings are particularly susceptible to damage due to constant motion, harsh environments, and heavy workloads. Understanding the common issues that arise with bearings and their associated components can help farmers and equipment operators identify problems early and prevent costly breakdowns. In this article, we will explore the most common issues with bearings and components in agricultural equipment and provide troubleshooting tips to help improve the performance and longevity of machinery.

Understanding Bearings in Agricultural Equipment

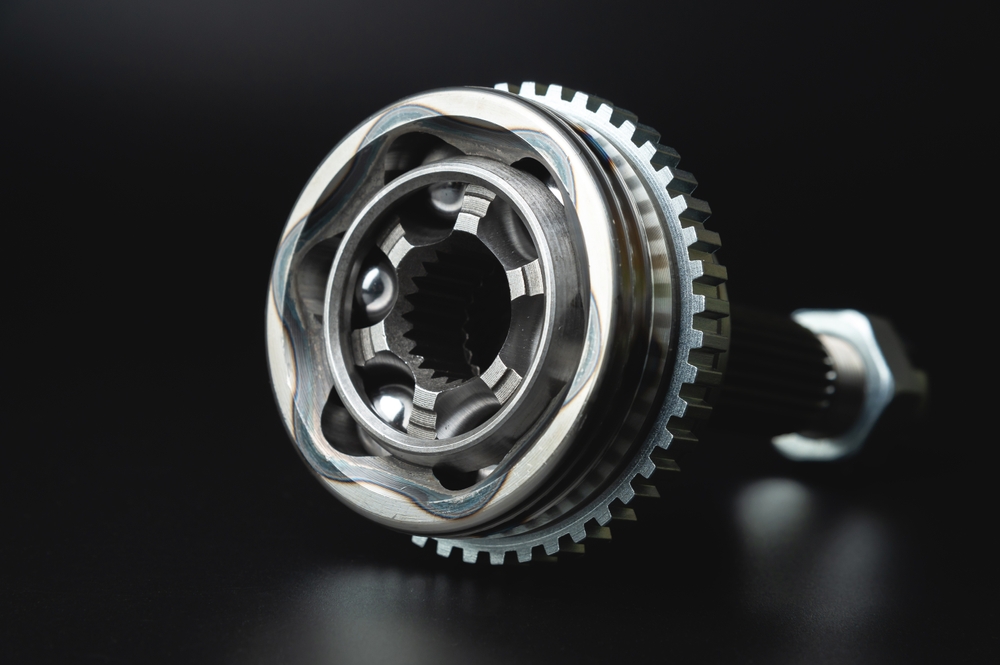

Bearings are crucial components in almost every piece of agricultural equipment. They allow machinery parts, such as wheels, gears, and axles, to move smoothly and with minimal friction. Bearings reduce the wear on metal parts and ensure that heavy-duty equipment operates with precision. There are various types of bearings, including ball bearings, roller bearings, and sleeve bearings, each designed to handle different loads and operating conditions. However, regardless of the type, bearings in agricultural machinery are subjected to harsh working conditions such as high-pressure loads, exposure to dirt, moisture, and extreme temperatures. As a result, farmers in Amarillo, TX, and other areas with a similarly rugged climate must be proactive in maintaining their bearings to prevent problems from arising.

Common Bearing Issues in Agricultural Equipment

One of the most common issues that agricultural equipment operators face is bearing failure. Bearing failure can occur for several reasons, and diagnosing the problem early can prevent further damage to machinery. Some of the most frequent bearing issues include overheating, contamination, misalignment, corrosion, and excessive wear.

Overheating is a frequent cause of bearing failure, particularly in high-load applications. The friction generated by rotating parts causes heat, and if this heat is not properly dissipated, it can damage the bearing. In severe cases, excessive heat can cause the bearing to seize up, which may result in the breakdown of other components or even complete equipment failure. Overheating can be caused by inadequate lubrication, improper load distribution, or malfunctioning cooling systems in agricultural machinery.

Another common issue is contamination. Bearings in agricultural equipment are often exposed to dirt, dust, moisture, and chemicals, all of which can contaminate the bearing and cause it to fail prematurely. When contaminants enter the bearing, they can create abrasive wear, increase friction, and ultimately lead to the bearing becoming inefficient. In environments like Amarillo, where dust storms and extreme weather conditions are not uncommon, contamination can be a significant challenge for operators.

Misalignment is another frequent problem with bearings in agricultural machinery. Misalignment occurs when the components that the bearing supports are not properly positioned or aligned. This can lead to uneven load distribution and increased friction, which, in turn, accelerates wear on the bearing. Misalignment is typically caused by improper installation or accidental damage to the machinery that throws the components out of alignment. In agricultural equipment, misalignment can also result from the heavy stresses placed on bearings during tasks like plowing or harvesting.

Corrosion is another issue that can significantly affect the performance of bearings in agricultural equipment. Bearings are often exposed to moisture, chemicals, and environmental factors, leading to rust and corrosion over time. Corrosion weakens the bearing material, which can lead to cracks, pitting, and other forms of damage that impair the bearing’s function. In Amarillo, where humidity and rainfall can fluctuate, corrosion can be an ongoing concern for farmers who need to ensure their bearings are well-protected from the elements.

Excessive wear is a natural consequence of using bearings in high-stress conditions, but it can also be accelerated by inadequate maintenance or operating the machinery under extreme conditions. If a bearing is not adequately lubricated or regularly inspected, the components may wear down prematurely. This is especially common in high-use equipment that is subjected to intense workloads, such as during peak planting or harvesting seasons.

Troubleshooting Tips for Bearings in Agricultural Equipment

To keep bearings in good working condition and avoid costly repairs, it is essential for agricultural equipment operators in Amarillo to implement a proactive approach to maintenance. Regular inspection and preventative measures can go a long way in ensuring the longevity and reliability of machinery. Here are some troubleshooting tips that can help address common bearing issues and prevent unnecessary breakdowns.

First and foremost, proper lubrication is crucial for maintaining the health of bearings. Bearings that are not lubricated properly or consistently can experience increased friction, leading to overheating and premature wear. It is essential to use the appropriate type of lubricant for each bearing, as different machines have different requirements. Grease or oil should be applied at regular intervals, and the condition of the lubricant should be monitored to ensure it remains clean and effective. Over-lubricating a bearing can also lead to issues, as excess lubricant can attract dirt and debris, which can damage the bearing. Operators should follow the manufacturer’s recommendations for lubrication intervals and amounts to prevent both over-lubrication and under-lubrication.

Regular inspection of the bearings is another key step in troubleshooting and preventing failures. Operators should visually inspect the bearings for signs of wear, such as cracks, discoloration, or pitting, and check for any signs of corrosion or contamination. Additionally, it is a good idea to inspect the seals around the bearing to ensure they are intact and functioning properly. Seals are designed to protect the bearing from dust, moisture, and other contaminants, so any damage to the seals can result in the bearing failing prematurely. If any irregularities are found during the inspection, it is important to replace the bearing immediately to avoid further damage to other parts of the equipment.

In cases where misalignment is suspected, operators should ensure that the machinery components are properly aligned. Misalignment can often be detected by unusual vibrations, excessive noise, or uneven wear on the bearing. It is important to check the alignment of the shaft, housing, and other parts that are connected to the bearing. If misalignment is detected, it should be corrected immediately to prevent further damage. In some cases, using alignment tools such as laser alignment systems can help ensure the machinery components are precisely aligned, reducing the risk of bearing failure.

To combat corrosion, it is important to protect bearings from exposure to moisture and harmful chemicals. Farmers should ensure that bearings are properly sealed and covered to prevent water or chemicals from getting inside. In some cases, bearings with special corrosion-resistant coatings can be used for added protection. Additionally, regular cleaning of the equipment can help remove any dirt, debris, or corrosive substances that may have built up around the bearing, ensuring that it remains in optimal condition.

Lastly, it is important to monitor the workload placed on bearings. Overloading bearings can lead to excessive wear and overheating, both of which can result in failure. Operators should follow the manufacturer’s specifications for load limits and avoid placing excessive stress on the machinery. If bearings are subject to heavy-duty applications, it may be necessary to upgrade to bearings that are designed for high-load conditions to ensure maximum performance and durability.

The Importance of Professional Help and Regular Maintenance

While regular maintenance and troubleshooting can go a long way in prolonging the life of bearings and agricultural equipment, there are times when professional assistance may be necessary. In Amarillo, TX, where agriculture is a key industry, having access to reliable repair and maintenance services is crucial. Professional technicians can help identify and resolve bearing-related issues that may be difficult to detect with a simple inspection. They can also provide expert advice on upgrading or replacing worn-out bearings to ensure that machinery continues to perform at its best.

By investing in regular professional maintenance, operators can extend the life of their bearings and equipment, reduce the risk of unexpected breakdowns, and ultimately save money in the long run. Additionally, working with professionals can help ensure that any new bearings or components are properly installed and aligned, minimizing the likelihood of future issues.

Conclusion

Bearings and components in agricultural equipment are critical for ensuring smooth operation and optimal performance. In Amarillo, TX, where the agricultural industry is vital, farmers and equipment operators must be proactive in addressing common bearing issues such as overheating, contamination, misalignment, corrosion, and excessive wear. By following proper maintenance practices, including lubrication, regular inspection, and addressing alignment and corrosion issues, farmers can prevent costly breakdowns and extend the life of their machinery. When in doubt, seeking professional help and investing in regular maintenance can help ensure that agricultural equipment continues to operate efficiently and reliably throughout the year.

Need Cotton Mill & Cotton Gin Components in Lubbock, TX?

Welcome to M.B. McKee Company, Inc. M.B. McKee Company, Inc. has been serving our local community of Lubbock since 1943. Locally owned and family operated, we provide great customer service and solutions for ongoing issues. With over 70 years of experience, our products, services, and engineering will always exceed your expectations. Our products include bearings, belts, chains, conveyor systems, gearing, lifts, motors, drives, product separation, tools, valves, and fittings. Our engineering division also provides general formulas, NEMA motor frames, elevator legs, screw and belt conveyors, lift charts, components from Baldor and Flexco, and various interchangeable parts. Contact us today to learn more about what we can do for you!

Categorised in: Mechanical Bearings

This post was written by Orlando Washington