Different Types of Mechanical Bearings Used in the Cotton Gin Industry

March 22, 2024 7:14 pm Leave your thoughts

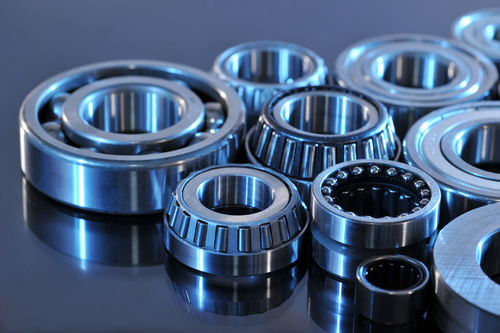

The cotton gin industry relies heavily on the use of mechanical bearings to ensure smooth and efficient operation of the machines. Bearings are essential components that help reduce friction between moving parts, allowing them to move freely and smoothly. In this blog, we will discuss some of the most common types of mechanical bearings used in cotton gins and their importance in the industry.

1. Ball Bearings:

Ball bearings are one of the most common types of mechanical bearings used in the cotton gin industry. They consist of small steel balls that roll between two grooved rings, reducing friction and enabling smooth rotation of shafts or axles. Ball bearings are ideal for high-speed applications and can handle both radial and thrust loads. In cotton gins, ball bearings are commonly used in the spindles and rotating components to ensure smooth operation and reduce wear and tear on the machine.

2. Roller Bearings:

Roller bearings are another type of mechanical bearings used in the cotton gin industry. Unlike ball bearings, roller bearings use cylindrical rollers instead of balls to reduce friction and support heavy radial loads. Roller bearings are ideal for applications where high radial loads are present, such as in the rollers and conveyors of a cotton gin. They are more durable and can handle heavier loads compared to ball bearings, making them suitable for heavy-duty applications in the cotton gin industry.

3. Plain Bearings:

Plain bearings, also known as bushings or sleeve bearings, are a type of mechanical bearings that do not contain any rolling elements. Instead, plain bearings use a sliding surface to reduce friction and support rotating components. Plain bearings are often used in low-speed and high-load applications in the cotton gin industry, such as in the drives and pulleys. They are simple in design, cost-effective, and require minimal maintenance, making them a popular choice for many cotton gin manufacturers.

4. Thrust Bearings:

Thrust bearings are designed to support axial loads and prevent movement along a shaft or axle. In the cotton gin industry, thrust bearings are commonly used in applications where heavy axial loads are present, such as in the cleaner and presser components. Thrust bearings come in various configurations, including ball, roller, and plain thrust bearings, depending on the specific application requirements. They help to reduce friction and ensure smooth operation of the components in the cotton gin.

5. Pillow Block Bearings:

Pillow block bearings are a type of mounted bearing that is commonly used in the cotton gin industry to support rotating shafts or axles. Pillow block bearings consist of a housing unit with a bearing mounted inside, providing a stable and secure mounting solution. They are easy to install and remove, making maintenance and replacement tasks more convenient for operators. Pillow block bearings are used in various applications in cotton gins, including in the main drive systems and the saw shafts.

6. Flange Bearings:

Flange bearings are another type of mounted bearing used in the cotton gin industry to provide support and stability to rotating components. Flange bearings consist of a flat mounting surface with a bearing attached, allowing for easy installation on a shaft or housing. Flange bearings are commonly used in applications where space is limited, such as in the cleaner and lint cleaner components of a cotton gin. They help to reduce friction and support the rotating parts, ensuring smooth and efficient operation of the machine.

Summary

Mechanical bearings play a crucial role in the cotton gin industry by reducing friction, supporting heavy loads, and ensuring smooth operation of the machines. From ball bearings and roller bearings to plain bearings and thrust bearings, each type of bearing has its unique attributes that make them suitable for specific applications in the cotton gin industry. By understanding the different types of mechanical bearings used in cotton gins, manufacturers can make informed decisions to optimize the performance and reliability of their machines.

Need Cotton Mill & Cotton Gin Components in Lubbock, TX?

Welcome to M.B. McKee Company, Inc. M.B. McKee Company, Inc. has been serving our local community of Lubbock since 1943. Locally owned and family operated, we provide great customer service and solutions for ongoing issues. With over 70 years of experience, our products, services, and engineering will always exceed your expectations. Our products include bearings, belts, chains, conveyor systems, gearing, lifts, motors, drives, product separation, tools, valves, and fittings. Our engineering division also provides general formulas, NEMA motor frames, elevator legs, screw and belt conveyors, lift charts, components from Baldor and Flexco, and various interchangeable parts. Contact us today to learn more about what we can do for you!

Categorised in: Cotton Gin Components, Cotton Mill Components, Mechanical Bearings

This post was written by admin